The Oregon Health Authority (OHA) recently implemented a set of temporary rules effective through June 28th of this year with the goal to establish a set of regulations for cannabis testing by October 1st. An investigation by The Oregonian highlighted some of the previous problems with cannabis testing in the state.

The most impactful rule changes include The NELAC Institute (TNI) mandatory standards for laboratories that the Oregon Environmental Laboratory Accreditation Program (ORELAP) will use to accredit labs. Initial rules in the Oregon medical cannabis program, HB 3460 from 2013, did not specify accreditation rules for cannabis testing.

ORELAP currently performs accreditation for lab testing under the Clean Air Act, Clean Water Act, Resource Conservation and Recovery Act and the Safe Drinking Water Act. The new cannabis testing rules will give ORELAP the authority to accredit and regulate cannabis labs in the state of Oregon.

Rodger Voelker, Ph.D., laboratory director of OG Analytical in Eugene, OR, believes these rules are monumental in establishing legitimacy in cannabis testing. “These new rules have major repercussions mainly because they require not only getting accreditation, but maintaining it with very strict requirements,” says Voelker. “That also includes procedural guidelines that very carefully outline the quality of laboratory practices and establishes a set of criteria for method validation.”

Voelker notes that two of the biggest changes are in quality control and data management. “The documentation they require is very thorough and strict with the idea that any aspect of an analysis can be replicated,” adds Voelker. “This is a real win for us in my opinion because now we have an agency that can issue the appropriate credentials as well as have the authority to make punitive measures.”

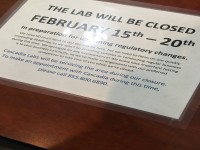

The timeline for implementation with temporary rules allows state regulators to work with laboratories to perform accreditation and bring laboratories up to speed. According to Shannon Swantek, ORELAP compliance specialist, products that dispensaries sell in medical and recreational markets are required to be tested under the new rules and in the analyte lists by an ORELAP accredited laboratory, starting on October 1st.

Swantek’s job is to accredit cannabis labs to the TNI standards, which is essentially very similar to ISO 17025, just with more prescriptive measures and the ability to pair with state agencies to enforce rules after accreditation. “The timeline for accreditation is dependent on how ready the lab is and how compliant they are to the TNI standard already,” says Swantek. “The culture had gotten so fraudulent that the legislature felt Oregon needed some serious, more strict rules in place.”

One of the biggest changes coming to Oregon cannabis testing is the new sampling requirement. “An accredited laboratory employee must take the sample because sampling is where a lack of training or outright fraud is skewing results, which occurs when a grower brings in a sample not representative of the batch,” adds Swantek. Sample preparation methods will also be required to be more robust to meet the action limits of pesticide testing in particular, helping to identify lower levels like parts-per-billion, according to Swantek.

Reports were also lacking key information in the past. The new rules will require more information such as the procedure used, the analyst carrying it out, dilution factors and any other information you need to theoretically reproduce the result. This will result in more accurate labels on products.

Many are concerned that the new lab testing requirements will raise the price of testing too much. In reality, those current prices are not realistic for accurate data, which points to the rampant fraud that ORELAP is trying to eradicate. “The old rules were written in such an ambiguous way that the prices were set by laboratories without a proper quality program or even without proper instrumentation,” says Swantek.

The accreditation process will require particularly robust quality control systems in labs. “Accreditation to the TNI Standard means that lab quality systems will require a documentation system, training procedures, record keeping, personnel requirements, organization details, proof of no conflicts of interest and corrective actions if noncompliant,” adds Swantek. “We single out each method or procedure, look at their raw data and proficiency testing and determine if they are meeting the technical requirements.”

According to Voelker, other industries have learned to adjust their costs with stringent lab testing rules. “I get that no one wants to pay more for lab testing, but the reality is that joining the world of commodities comes with additional costs to ensure consumer safety,” says Voelker. These rule changes will undoubtedly bring more consistency to Oregon’s cannabis industry with accurate lab testing and help the OHA shed more light on issues surrounding consumer safety.