The American Oil Chemists’ Society (AOCS) held its annual conference in Salt Lake City this week, with a track focused on cannabis testing and technology. Cynthia Ludwig, director of technical services at AOCS and member of the advisory panel to The Emerald Test, hosted the two-day event dedicated to all things extraction technology and analytical testing of cannabis.

Highlights in the discussion surrounding extraction technologies for the production of cannabis concentrates included the diversity of concentrate products, solvent selection for different extraction techniques and the need for cleaning validation in extraction equipment. Jerry King, Ph.D., research professor at the University of Arkansas, began the event with a brief history of cannabis processing, describing the physical morphologies in different types of extraction processes.

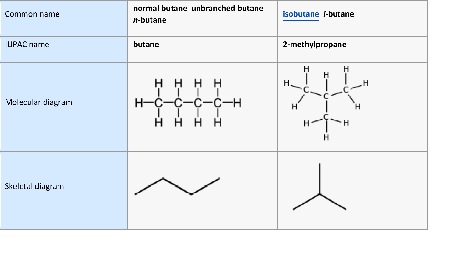

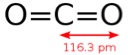

Michael McCutcheon, research scientist at Eden Labs, laid out a broad comparison of different extraction techniques and solvents in use currently. “Butane is a great solvent; it’s extremely effective at extracting active compounds from cannabis, but it poses considerable health, safety and environmental concerns largely due to its flammability,” says McCutcheon. He noted it is also very difficult to get USP-grade butane solvents so the quality can be lacking. “As a solvent, supercritical carbon dioxide can be better because it is nontoxic, nonflammable, readily available, inexpensive and much safer.” The major benefit of using supercritical carbon dioxide, according to McCutcheon, is its ability for fine-tuning, allowing the extractor to be more selective and produce a wider range of product types. “By changing the temperature or pressure, we can change the density of the solvent and thus the solubility of the many different compounds in cannabis.” He also noted that, supercritical carbon dioxide exerts tremendous pressure, as compared to hydrocarbon solvents, so the extraction equipment needs to be rated to a higher working pressure and is generally more expensive.

John A. Mackay, Ph.D., senior director of strategic technologies at Waters Corporation, believes that cannabis processors using extraction equipment need to implement cleaning SOPs to prevent contamination. “There is currently nothing in the cannabis industry like the FDA CMC draft for the botanical industry,” says Mackay. “If you are giving a child a high-CBD extract and it was produced in equipment that was previously used for another strain that contains other compounds, such as CBG, CBD or even traces of THC extract, there is a high probability that it will still contain these compounds as well as possibly other contaminants unless it was properly cleaned.” Mackay’s discussion highlighted the importance of safety and health for workers throughout the workflow as well as the end consumer.

Jeffrey Raber, Ph.D., chief executive officer of The Werc Shop, examined different testing methodologies for different applications, including potency analyses with liquid chromatography. His presentation was markedly unique in proposing a solution to the currently inconsistent classification system for cannabis strains. “We really do not know what strains cause what physiological responses,” says Raber. “We need a better classification system based on chemical fingerprints, not on baseless names.” Raber suggests using a chemotaxonomic system to identify physiological responses in strains, noting that terpenes could be the key to these responses.

Dylan Wilks, chief scientific officer at Orange Photonics, discussed the various needs in sample preparation for a wide range of products. He focused on sample prep and variation for on-site potency analysis, which could give edibles manufacturers crucial quality assurance tools in process control. Susan Audino, Ph.D., chemist and A2LA assessor, echoed Wilks’ concerns over sample collection methods. “Sampling can be the most critical part of the analysis and the sample size needs to be representative of the batch, which is currently a major issue in the cannabis industry,” says Audino. “I believe that the consumer has a right to know that what they are ingesting is safe.” Many seemed to share her sentiment about the current state of the cannabis testing industry. “Inadequate testing is worse than no testing at all and we need to educate the legislators about the importance of consumer safety.”

46 cannabis laboratories participated in The Emerald Test’s latest round of proficiency testing for potency and residual solvents. Cynthia Ludwig sits on the advisory panel to give direction and industry insights, addressing specific needs for cannabis laboratories. Kirsten Blake, director of sales at Emerald Scientific, believes that proficiency testing is the first step in bringing consistency to cannabis analytics. “The goal is to create some level of industry standards for testing,” says Blake. Participants in the program will be given data sets, judged by a consensus mean, so labs can see their score compared to the rest of the cannabis testing industry. Proficiency tests like The Emerald Test give labs the ability to view how consistent their results are compared to the industry’s results overall. According to Ludwig, the results were pleasantly surprising. “The results were better than expected across the board; the vast majority of labs were within the acceptable range,” says Ludwig. The test is anonymous so individual labs can participate freely.

The AOCS cannabis working groups and expert panels are collaborating with Emerald Scientific to provide data analytics reports compliant with ISO 13528. “In the absence of a federal program, we are trying to provide consistency in cannabis testing to protect consumer safety,” says Ludwig. At the AOCS annual meeting, many echoed those concerns of consumer safety, proposing solutions to the current inconsistencies in testing standards.