In the realm of consumer safety, minimum standards form a critical safety net that allows businesses and regulators alike with necessary guidelines. From our food and medicines, railroad tracks to bicycle helmets, crayons to cribs, standards are everywhere. Knowing where the lanes are and how to move inside of them provides the structure needed to guide manufacturers forward. And the cannabis and hemp industry is no exception. Why would it be?

In this series of articles, we will explore specific ASTM International standards that have already been developed and published by its Committee on Cannabis (commonly referred to by its Committee designation number – D37). With a frustrating lack of federal clarity, states are increasingly adopting these standards directly into their rules — and for good reason! These standards have gone through an extensive and rigorous process of achieving consensus, adhering to the principles set out by the World Trade Organization to reduce technical barriers to trade. These principles cover openness, balance, and transparency, and are one of many reasons why ASTM standards are confidently adopted into regulations by the US Federal Government. It is no wonder state regulators are increasingly leaning into those standards with confidence when creating rules and regulations for operators in the cannabis industry.

There are numerous benefits to standards adoption, including taking the guesswork out of the “how,” and streamlining operations, particularly when companies wish to scale up and expand. To provide color and context to the fuzzy world of standards, we will include insights from ASTM committee members who were involved in the hands-on process of standards development, including Kim Stuck of Allay Consulting, Dr. David Nathan of D4DPR (Doctors For Drug Policy Reform), and Dr. John DeVries.

“ASTM has been around for over a century, and it is common practice for governments to adopt the standards that have been written by their committees. It takes so much time and effort to put together standards to create safe and consistent products that it just makes sense for governments to adopt already written standards from a trusted source such as ASTM rather than spending the time and money writing a set of their own that will most likely mirror the ASTM standards. The cannabis standards that we have been developing since 2017 have also been written by experts in the industry so that no corner of the industry will be left unregulated,” said Kim Stuck of Allay Consulting, a strategic partner of The GMP Collective, and a participating member of the ASTM D37 Cannabis Committee.

“The process that ASTM uses has been proven to create the most well-rounded and consistent standards, and I am proud to be a part of the process,” Stuck continued. “ASTM International plays a pivotal role in the cannabis industry by providing comprehensive, science-based standards that guide the production, testing, and distribution of cannabis products. The development and implementation of these standards ensure consistent quality, safety, and efficacy across the industry, fostering trust among consumers, regulators, and industry stakeholders.”

HACCP Systems

The same program that was developed by the US Army, NASA, and Pillsbury to keep astronauts from getting sick in outer space is arguably one of the best standards for any cannabis operator to implement in their own operation. The Subcommittee on Quality Management Systems (D37.02) realized and did just that, developing the HACCP System standard, which provides general guidance for implementation in order to prevent, control, or minimize hazards (biological, chemical, or physical) to an acceptable level. The standard can be accessed by anyone with an active ASTM membership, or purchased individually for just $63. As of publication, this standard has been adopted in 3 states, including Oklahoma where it is recommended, New Mexico where it is required for medical applications, and Colorado, which is required as of July 2024 for growers who want a microbial-reduced testing allowance.

“Regarding the specific HACCP (Hazard Analysis and Critical Control Points) standard I was involved in developing, its application in the cannabis industry establishes a proactive approach to identifying, evaluating, and controlling potential hazards throughout the production and distribution process. This standardization is vital for ensuring product safety, quality assurance, and compliance with regulatory requirements.

“HACCP helps the industry minimize risks and prevent contamination, leading to safer products for consumers. By implementing these standards, businesses can provide greater transparency and build consumer confidence in their products. This, in turn, supports the industry’s growth and fosters a safer marketplace while also mitigating risk and preventing costly recalls and fines.

“Regulators and lawmakers rely on such standards because they offer a structured and consistent framework for assessing safety and quality in the industry. Having robust, science-based standards like HACCP helps establish clear benchmarks for producers to meet, ensuring consumer safety and facilitating effective regulation and enforcement. By adhering to these standards, the cannabis industry can gain legitimacy and support from both regulators and consumers,” added Stuck.

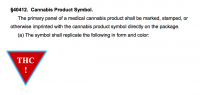

Universal Symbol

The most symbolic standard published by the D37 Cannabis Committee is just that: a valuable consumer-facing symbol recommended for use on the packaging of any consumer product that may contain a level of intoxicating cannabinoids. The symbol can be stamped onto edibles like gummies and chocolate, and/or included on packaging. The standard solves an issue that came out of the patchwork regulatory systems from state to state, where each state, upon rolling out rules and regulations, essentially made it up as they went along, developing their own symbols due to not being able to point to a universal standard. This symbol now exists, paving the way for a streamlined process as new states legalize cannabis for medical or adult use.

Dr. David Nathan, Founder and Past President of D4DPR, was a key leader in the development of this standard which is already in adoption across multiple states. “The International Intoxicating Cannabinoid Product Symbol (IICPS) is a harmonized, universal cannabis product symbol that was developed and approved as consensus standard ASTM D8441 by ASTM International through a unanimous vote of over 200 professionals and experts from the public and private sectors. The National Technology Transfer and Advancement Act (NTTAA) mandates federal use of consensus standards, so the IICPS is poised to become the national cannabis product symbol when cannabis is legalized at the federal level,” Dr. Nathan said. The standard can be accessed through ASTM membership or purchased for a fee of $55.

Since its introduction in 2022, the IICPS has already been incorporated into the universal symbol of four U.S. states: Montana, South Dakota, New Jersey, and Vermont, and has been proposed in recent rulemaking in the State of Arkansas. Several other states are currently considering its adoption,” Dr. Nathan explained.

In 2023, 22 organizations representing public health, social justice, patient, consumer, and industry advocacy groups signed an open letter to regulators in the United States and around the world supporting universal adoption of the IICPS. If all states where cannabis is legal were to adopt this new standard moving forward, the result would be a significant time and cost savings in the long-run for companies who wish to expand across state lines. The symbol is clear, recognizable, and adheres to international interpretations based on color, shape, and other symbology factors. These factors were evaluated by a robust consumer research study to verify the effectiveness and intent of the symbol which was discussed in a webinar available on demand here.

To understand the impacts of many of the current symbols used in different states, written testimony submitted to the New York Office of Cannabis Management titled “A Symbolic Failure of Cannabis Regulation,” provides a colorful example. In it, Dr. Nathan states the following:

“The OCM symbol requires four-color printing, which is expensive. In a regulatory space intended to right the wrongs of the failed War on Drugs, the OCM symbol creates a barrier to entrepreneurs from historically oppressed communities who lack the capital to invest in costly packaging.

“The OCM symbol also violates numerous consensus standards, which are technical specifications issued by standards organizations like NIST, ASTM, and ISO. They are developed in an open environment to ensure public safety and promote best practices through collaboration by expert volunteers in the public and private sectors. Standards organizations have flourished since the 19th century, and their standards apply to everything from airplanes to zippers.”

Water Activity Controls

Dr. Jonathan DeVries, who provides food science services in regulatory and litigation matters, was the technical contact involved in developing the first two ASTM cannabis standards — developed to control water activity in cannabis flower that directly impacts both safety and quality of the product.

Dr. DeVries explained: “The first two methods adopted by ASTM committee D37 on Cannabis were ASTM D8196 Standard Practice for Determination of Water Activity (aw) in Cannabis Flower and ASTM D8197 Standard Specification for Maintaining Acceptable Water Activity (aw) Range (0.55 to 0.65) for Dry Cannabis Flower Intended for Human/Animal Use. During the early life stages of ASTM D37, cannabis growers, processors, and users stressed the importance of controlling the water activity of cannabis flower for safety and quality. All involved were generally aware that if the water activity was too high, microorganism growth, particularly mold, would damage the flowers rendering them unsafe (to say nothing of unpalatable). Similarly, cannabis flower that had a water activity that was too low (i.e the cannabis was too dry) could lead to dissatisfaction by the ultimate consumer because of handling losses due to fragility, loss of terpenes due to volatiles losses due to high burn temperatures during smoking, and unduly harsh characteristics of the smoke.” Both of those standards can be accessed through ASTM membership or purchased for a fee.

“Controlling the water activity to this range also is very logical during analysis, regulation, and commerce. Cannabis, properly dried and cured, then controlled to water activity 0.55 to 0.65 will exhibit very little variation in weight due to moisture change (controlling to a water activity range is typically more effective than controlling moisture directly) or loss or key volatiles that are part of the cannabis experience.

“As the technical contact for ASTM D8196 and D8197, I was always impressed with the ASTM processes, and of course, I was also impressed by the eagerness and willingness of those involved in providing safe, high-quality cannabis to be engaged in the process and share their extensive knowledge and experience to produce the optimum standard to meet the need.”

A Collaborative Effort

With more than 50 standards produced and published by the D37 Committee on Cannabis at ASTM, and another 50 more currently in development, there’s great opportunity to take the guesswork out of everything from Quality Management Systems, to Devices & Appliances, to Personnel Training, Assessment & Credentialing, and everything in between.

Stay tuned for the evolution of this article series, where we will explore more of these standards in order to understand their impact on ensuring consumer safety and streamlining what has been a chaotic patchwork of imperfect regulations and practices across the industry. By embracing standardized protocols and best practices, stakeholders can enhance transparency, build trust with consumers, and foster a more robust and sustainable cannabis market. Through collaboration and adherence to these evolving standards, we can pave the way towards a safer and more accountable cannabis and cannabinoid industry for all.

ASTM International meets the World Trade Organization (WTO) principles for developing international standards, and maintains the attributes outlined in the

ASTM International meets the World Trade Organization (WTO) principles for developing international standards, and maintains the attributes outlined in the