When processing cannabis, in any form, it is critical to remember that it is a product intended for human consumption. As such, strict attention must also be paid to food safety as well. With more and more states legalizing either medical or recreational cannabis, the potential for improper processing of the cannabis triggering an illness or death to the consumer is increasing.

The FDA Food Safety Modernization Act (FSMA) is the new food safety law that has resulted in seven new regulations, many which directly or indirectly impact the production and processing of cannabis. Under FSMA regulations, food processors must identify either known or reasonably foreseeable biological, chemical or physical hazards, assess the risks of each hazard, and implement controls to minimize or prevent them. The FSMA Preventive Controls for Human Foods (PCHF) regulation contains updated food “Good Manufacturing Practices (cGMPs) that are in many cases made a requirement in a state’s medical or recreational cannabis laws. These cGMPs can be found in 21 CFR 117 Subpart B.

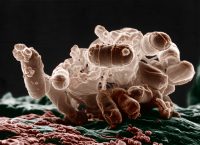

It is imperative that cannabis manufacturers have a number of controls in place including management of suppliers providing the raw material.Food safety risks in cannabis processing could originate from bacteria, cleaning or agricultural chemicals, food allergens or small pieces of wood, glass or metal. The hazards that must be addressed could be natural, unintentionally introduced, or even intentionally introduced for economic benefit, and all must be controlled.

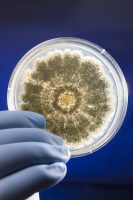

It is unlikely that high heat, used in other food products to remove bad bacteria would be used in the processing of cannabis as many of its desirable compounds are volatile and would dissipate under heating conditions. Therefore, any heat treatment needs to be carefully evaluated for effectiveness in killing bacterial pathogens while not damaging the valuable constituents of cannabis. Even when products are heated above temperatures that eliminate pathogens, if the raw materials are stored in a manner that permits mold growth, mycotoxins produced by molds that have been linked to cancer could be present, even after cooking the product. Storage of raw materials might require humidity controls to minimize the risk of mold. Also, pesticides and herbicides applied during the growth and harvesting of cannabis would be very difficult to remove during processing.

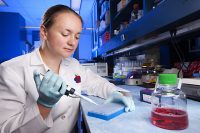

It is imperative that cannabis manufacturers have a number of controls in place including management of suppliers providing the raw material. Other controls that must be implemented include proper cannabis storage, handling and processing as well as food allergen control, and equipment/facility cleaning and sanitation practices. Processing facilities must adhere to Good Manufacturing Practices (GMP’s) for food processing, including controls such as employee hand washing and clothing (captive wear, hair nets, beard nets, removal of jewelry, and foot wear) that might contribute to contamination. A Pest Control plan must be implemented to prevent fecal and pathogen contamination from vermin such as rodents, insects, or birds.

Processing facilities must be designed for proper floor drainage to prevent standing water. Processing air should be properly filtered with airflow into the cannabis processing facility resulting in a slightly higher pressure than the surrounding air pressure, from the clean process area outwards. Toilet facilities with hand washing are essential, physically separated from the process areas. Food consumption areas must also be physically separate from processing and bathroom areas and have an available, dedicated hand sink nearby. Employee training and company procedures must be effective in keeping food out of the processing area. Labels and packaging must be stored in an orderly manner and controlled to prevent possible mix-up.Cleaning of the processing equipment is critical to minimize the risk of cross contamination and microbial growth.

Written food safety operational procedures including prerequisite programs, standard operating procedures (SOP’s), etc. must be implemented and monitored to ensure that the preventive controls are performed consistently. This could be manual written logs, electronic computerized data capture, etc., to ensure processes meet or exceed FSMA requirements.

A written corrective action program must be in place to ensure timely response to food safety problems related to cannabis processing problems when they occur and must include a preventive plan to reduce the chance of recurrence. The corrective actions must be documented by written records.

Supply chain controls must be in place. In addition, a full product recall plan is required, in the event that a hazard is identified in the marketplace to provide for timely recall of the contaminated product.

Cleaning of the processing equipment is critical to minimize the risk of cross contamination and microbial growth. The processing equipment must be designed for ease of cleaning with the minimum of disassembly and should conform to food industry standards, such as the 3-A Sanitary Standards, American Meat Institute’s Equipment Standards, the USDA Equipment Requirements, or the Baking Industry Sanitation Standards Committee (BISSC) Sanitation Standards ANSI/ASB/Z50.2-2008.

Serious food borne contaminations have occurred in the food industry, and cannabis processing is just as susceptible to foodborne contamination. These contaminations are not only a risk to consumer health, but they also burden the food processors with significant costs and potential financial liability.

Anyone processing cannabis in any form must be aware of the state regulatory requirements associated with their products and implement food safety programs to ensure a safe, desirable product for their customers.