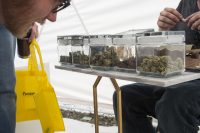

Willamette Week, a Portland-based publication, is hosting the 2017 Cultivation Classic with Farma, Cascadia Labs, Phylos Bioscience and the Resource Innovation Institute on May 12th. The event is a benefit for the Ethical Cannabis Alliance, an organization that promotes sustainability, labor standards and education surrounding the integrity and ethics of growing cannabis. Cultivation Classic is a competition for pesticide-free cannabis grown in Oregon, according to a press release.

Photo: Bridget Baker, 92bridges.com

While the event’s focus is on the competition, it is just as much a celebration of the craft cannabis community in Oregon. This year’s competition incorporates scientific collaboration like genetic sequencing for the winners by Phylos Bioscience and carbon accounting for all competitors. Keynote speakers include Ethan Russo, medical director of PHYTECS and Dr. Adie Po, co-founder of Habu Health. Congressman Earl Blumenauer, a prominent cannabis legalization advocate in Oregon, will also be speaking at the awards ceremony. You can check out the full schedule and speaker lineup here.

Raymond Bowser, breeder at Home Grown Natural Wonders, is a judge for this year’s Cultivation Classic. He speaks at cannabis conferences around the country and his business created a number of different strains, so he has experience with a myriad of growers and strains. “This time around everyone has really stepped up their game,” says Bowser. “The entries are noticeably better than last year.” When looking at the different samples sent to him, he sees a few key factors as most important in judging the quality. “What I am looking for is simple; a nice smell and a decent look, generally speaking,” says Bowser. “Aesthetics can tell you a lot about how it was grown, temperature changes and the overall care taken in cultivating and curing the flower.” For him, flavor, smell and aesthetics are the big variables to consider.

Those are factors that his company holds to high standards in their work, so he judges the samples based on the same variables. “It is what we strive for in our gardens and so far the samples I have tried are fantastic in that regard,” says Bowser. In other competitions that Bowser has judged in the past, they sent him between 40 and 60 strains to judge in seven days. “That is not conducive to a fair evaluation,” says Bowser. “Here, we are getting fourteen or so different strains, so we can sample one strain a day which is how I personally like to do it.”

Bowser is supportive of Cultivation Classic because of their emphasis on the craft industry. “We talk about craft cannabis and breeding craft cultivars at conferences around the country,” says Bowser. “With the rec industry growing so much, we see so many people cutting corners to save money, that it is refreshing to see growers take pride in the craft.” He also stresses the need for good lab testing and sound science in the trade. “I am big on lab testing; it is very important to get all the right analytics when creating strains,” says Bowser. “Cascadia is a solid choice for the competition; they have been a very good, consistent lab.” Emphasizing the local, sustainability-oriented culture surrounding the craft market, Bowser is pleased that this competition supports that same message. “We need to stay true to our Oregon roots and continue to be a clean, green, granola-eating state.”

Cascadia Labs is conducting the pesticide and cannabinoid analytics for all submissions and Phylos Bioscience will perform testing for the winners. According to Julie Austin, operations manager at Cascadia Labs, pesticide testing for the Oregon list of analytes was of course a requirement. “Some of the samples submitted had previous tests from us or from other accredited labs, but if they didn’t have those results we did offer a comprehensive pesticide test,” says Austin. The competition’s fee for submission includes the potency and terpenes analysis.

Jeremy Sackett, director of operations at Cascadia Labs, says they test for 11 cannabinoids and 21 terpenes. The samples are divided into groups of THC-dominant samples, CBD-dominant samples and samples with a 1:1 ratio of the two. “The actual potency data will be withheld from judges and competitors until the day of the event,” says Sackett. “We are data driven scientists, but this time we want to have a little fun and bring the heart of this competition back to the good old days: when quality cannabis was gauged by an experience of the senses, not the highest potency number.” The event will take place on May 12th at Revolution Hall in Portland, Oregon. Click here to get tickets to the event.